CIS Belt Weighers provide the most rugged and reliable solution to the industrial challenge of being able to weigh accurately material on a moving conveyor belt. With this, it is now possible to solve applications where throughput and consumption rates have to measured and controlled.

CIS Belt Weighers are custom-built to the requirement of the application after our engineers have visited the customer’s site and studied the relevant aspects of the process. The system provides reports on the instantaneous flow rate, totalised mass flow rate, etc.

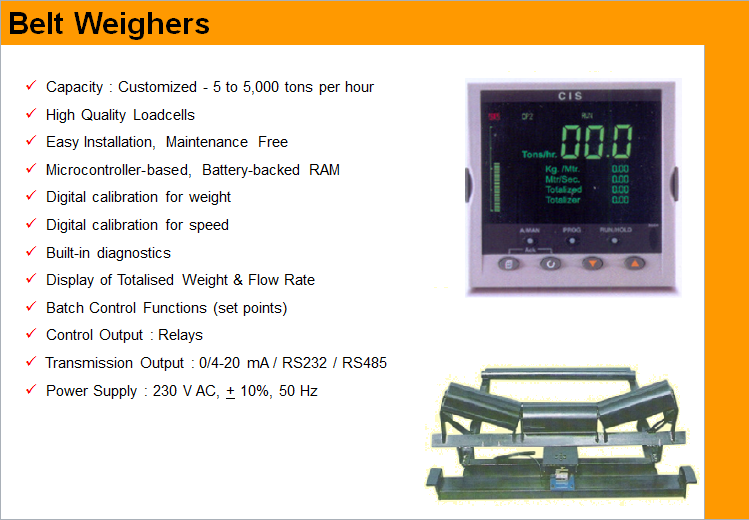

CIS manufacture state of art dynamic weighing controllers BS Series and Precision weighing frame to obtain best accuracy in its class.

Multiple Idler Belt Weigher System that consists of multiple idler sets mounted on a frame which is mounted on four load cells. Typical System accuracy can be 0.5% or Better.

– Power Plant; Steel Plant; Cement and Fertilizer Plant; Mines; Quarries and Many More.